Our financial management is bolstered by the Tower Loan System, allowing us to invest in cutting-edge technologies and employee training while maintaining financial stability. Meanwhile, the Vertical Automated Storage System ensures swift material access and efficient space utilization, keeping our operations running smoothly.

With XPO Smart logistics and Automated Logic Zs Sensors, we continue to push the boundaries of automation, striving for smarter, more efficient operations that surpass our clients' expectations.

At Gulf States Saw & Machine Co., our pursuit of innovation and excellence knows no bounds. Through the adoption of groundbreaking technologies like the HK Smart Cell and Smart Tower Automated Loading Systems, we set new benchmarks and drive progress in the industrial sector, staying ahead of the competition and delivering unparalleled value to our clients.

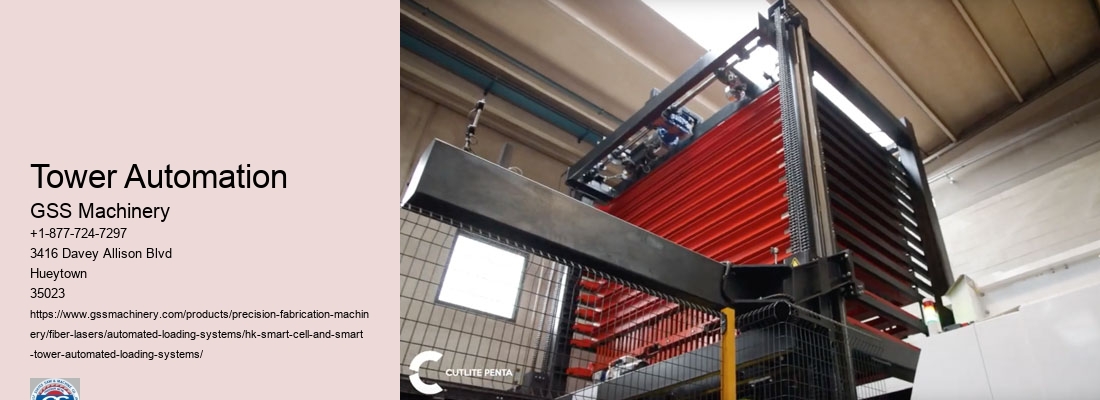

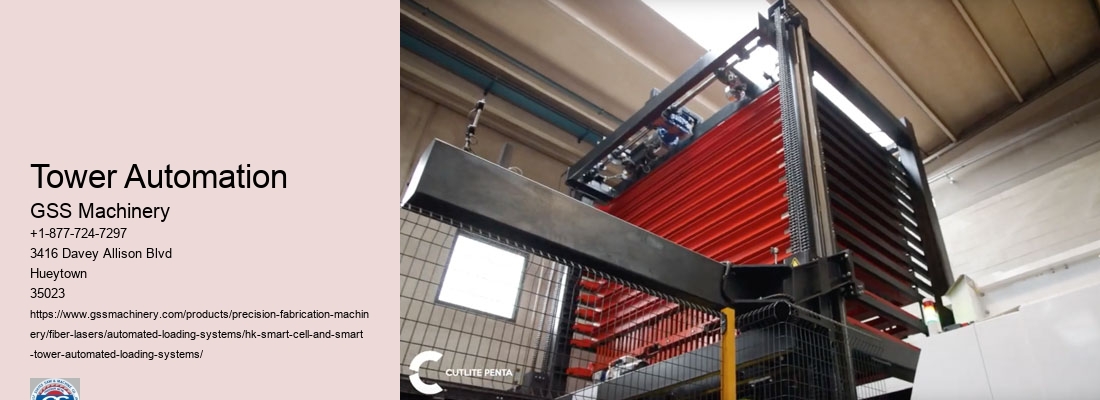

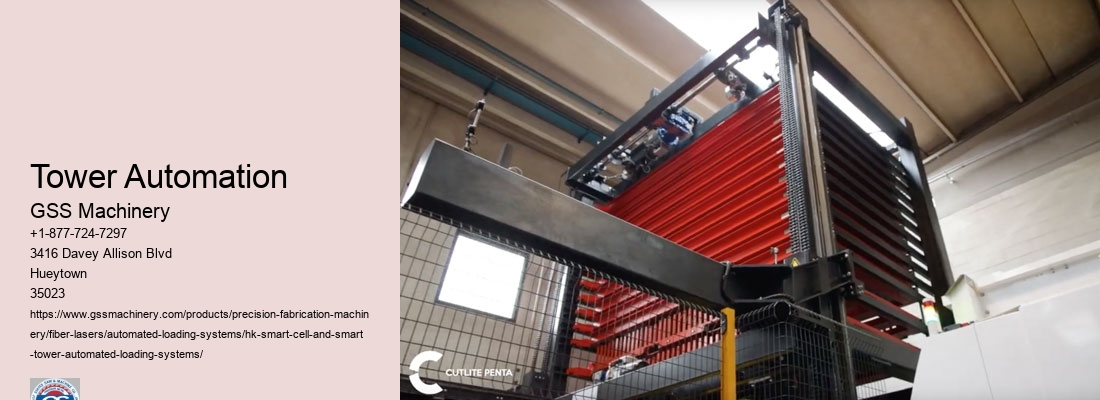

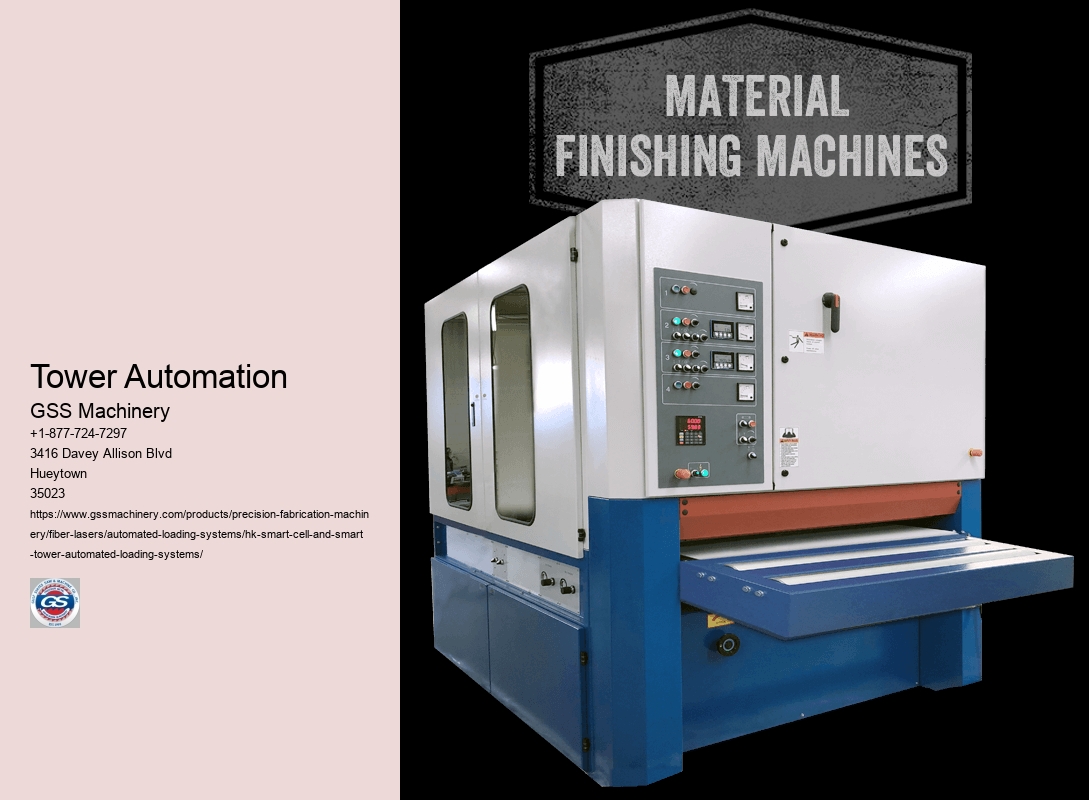

Operations The integration of HK Smart Cell and Smart Tower Automated Loading Systems (Smart Tower Automated Loading Systems) offers an advanced solution for enhancing efficiency in warehouse and manufacturing environments. By centralizing control and automating the loading process, these systems significantly improve throughput and accuracy. With HK Smart Cell and Smart Tower Automated Loading Systems, businesses can achieve faster cycle times and reduced labor costs, while maintaining high levels of precision and reliability in their operations. This innovative approach to material handling is pivotal for industries looking to optimize productivity and streamline their logistical frameworks..At Gulf States Saw & Machine Co., we're dedicated to staying ahead of the curve by integrating cutting-edge technologies into our operations. Optimization Our investment in Automated Storage Tower systems represents a significant step forward in inventory management, allowing us to work smarter, not harder, and boost productivity across the board.

Through our partnership with Smart-tek Automated Services Inc., we've tailored automation solutions to address the specific challenges of our industry. Their expertise in adapting technologies like the 3k Smart Amp and the 5 Ton Load Cell ensures that our operations run seamlessly and efficiently.

Our commitment to innovation is evident in our Automated Truck Loading Systems, which revolutionize the loading process, minimizing downtime and maximizing customer satisfaction with lightning-fast speed and pinpoint accuracy.

The integration of Automated Loading and Unloading Systems into our logistics streamlines the movement of goods, improving efficiency and ensuring products are stored in optimal conditions until they're ready to ship.

With the implementation of OSI Smart Grid technology, we gain real-time insights into our energy usage, allowing us to operate sustainably while maintaining peak efficiency.

Our Automated Parking Tower optimizes space and boosts employee productivity by automating vehicle storage, freeing up time for other essential tasks.

Every component, from Automated Logic Rnet to Automated Logic Room Sensor, plays a vital role in maintaining optimal conditions for machinery and personnel, ensuring consistent product quality and worker safety.

Our financial management is supported by the Tower Loan System, enabling us to invest in cutting-edge technologies and employee training while maintaining financial stability. Meanwhile, the Vertical Automated Storage System ensures efficient material access and space utilization, keeping our operations running smoothly.

With XPO Smart logistics and Automated Logic Zs Sensors, we're continuously striving for smarter, more efficient operations that exceed our clients' expectations.

At Gulf States Saw & Machine Co., our commitment to innovation drives us to explore new possibilities and set new standards in the industrial sector, ensuring we deliver unmatched value to our clients while staying ahead of the competition.

Systems Monitoring

At Gulf States Saw & Machine Co., we are proud to be at the forefront of industrial innovation, integrating advanced solutions such as the HK Smart Cell and Smart Tower Automated Loading Systems into our operations. Networks This cutting-edge technology streamlines the material handling processes, significantly enhancing productivity and safety across various sectors.

The integration of HK Smart Cell and Smart Tower Automated Loading Systems has revolutionized the way we manage logistics and inventory. By adopting this technology, we have been able to reduce manual handling, minimize errors, and accelerate the overall pace of our warehouse operations. The Smart Tower Automated Loading Systems, in particular, are designed to facilitate smooth and efficient loading and unloading activities, which are crucial in maintaining a swift flow of operations.

Our facility utilizes the HK Smart Cell & Smart Tower Automated Loading Systems to optimize space and improve the precision of our loading tasks.

The technology's backbone, the HK Smart Cell with Smart Tower Automated Loading Technology, incorporates advanced sensors and software that communicate seamlessly to automate tasks traditionally done by manual labor. This not only saves time but also significantly reduces the risk of workplace injuries.

We have equipped several of our workstations with HK Smart Cell and Smart Tower Auto-loading Systems, which are pivotal in managing high-volume tasks that require precision and repeatability. With these systems in place, our clients benefit from faster turnaround times and lower production costs, as the automated process reduces the need for repeated quality checks and manual corrections.

HK Systems AGV is another component we have integrated.

Automated Logic Room Sensors are used in smart buildings to monitor environmental conditions like temperature, humidity, and occupancy, which helps in optimizing energy usage and ensuring comfort.

The HK Smart Cell provides centralized control and monitoring capabilities, allowing for seamless integration and coordination of automated tasks within industrial and manufacturing settings.

JR Automation's Tote Stacker enhances warehouse operations by automating the stacking and storage of totes, reducing manual handling, and increasing storage density and retrieval speeds.